CONFIDENTIAL UTILITY COMPANY

Location: Southern California

Client: Confidential

Role: General Contractor

Project Value: Confidential

Size: 144,000 SF

Having a long-term working relationship with this utilities company, our team was engaged to manage the construction of upgrading aging infrastructure and the expansion of their telecom space.

One of the main challenges of this data center upgrade project was working within the active facility including the NERC-CIP designated areas that require special entry access and have full-time guards. This effort required extensive scheduling and coordination on our behalf. NERC-CIP areas included all critical areas key to their infrastructure, such as the data center, the control room that houses their SmartConnect technology, the printing facility, and the tape storage room.

Our team drove the construction around these constraints successfully by implementing a proven method of procedure (MOP) process. The MOP is a detailed step-by-step wok plan customized for each critical operation that includes a specialized safety plan, listing of key personnel, detailed step-by-step actions in order of implementation, and a detailed back-out plan to restore function in case of unexpected occurrences.

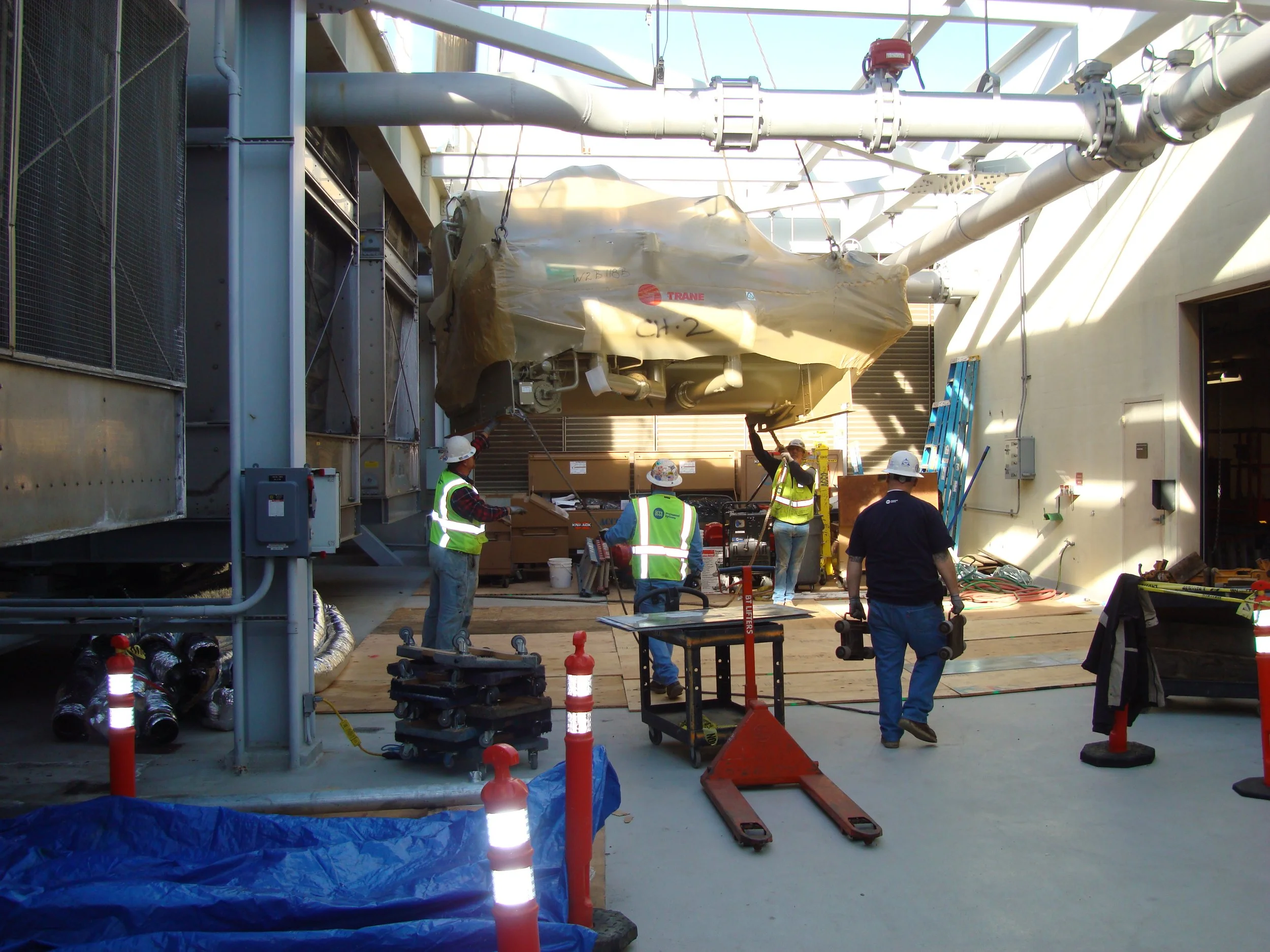

Overall the team replaced three existing, older 550-ton chillers and added a fourth 550-ton chiller. The team upgraded the building management system (BMS), and the fire protection system by removing an old halon system and installing a new FM-200 system and a new VESDA system. Existing air handlers were also modified, and new bacteria control systems on the air handlers were provided. CRAC units, a total of 18, were replaced, along with the existing generator day tanks, fuel lines, and supply pumps.

In addition, we developed a building information model (BIM) for the new telecom rooms, battery rooms, and the main point of entry room (MPOE). We also executed a client developed environmental controls standard, which included micro-cleaning, dust barriers and protection, particulate monitoring, temperature and humidity monitoring to ensure that the environment around the live equipment was protected.

As a result of our due diligence and experience working in live data center environments, the expansion and the infrastructure upgrades were completed without any interruption to operations.